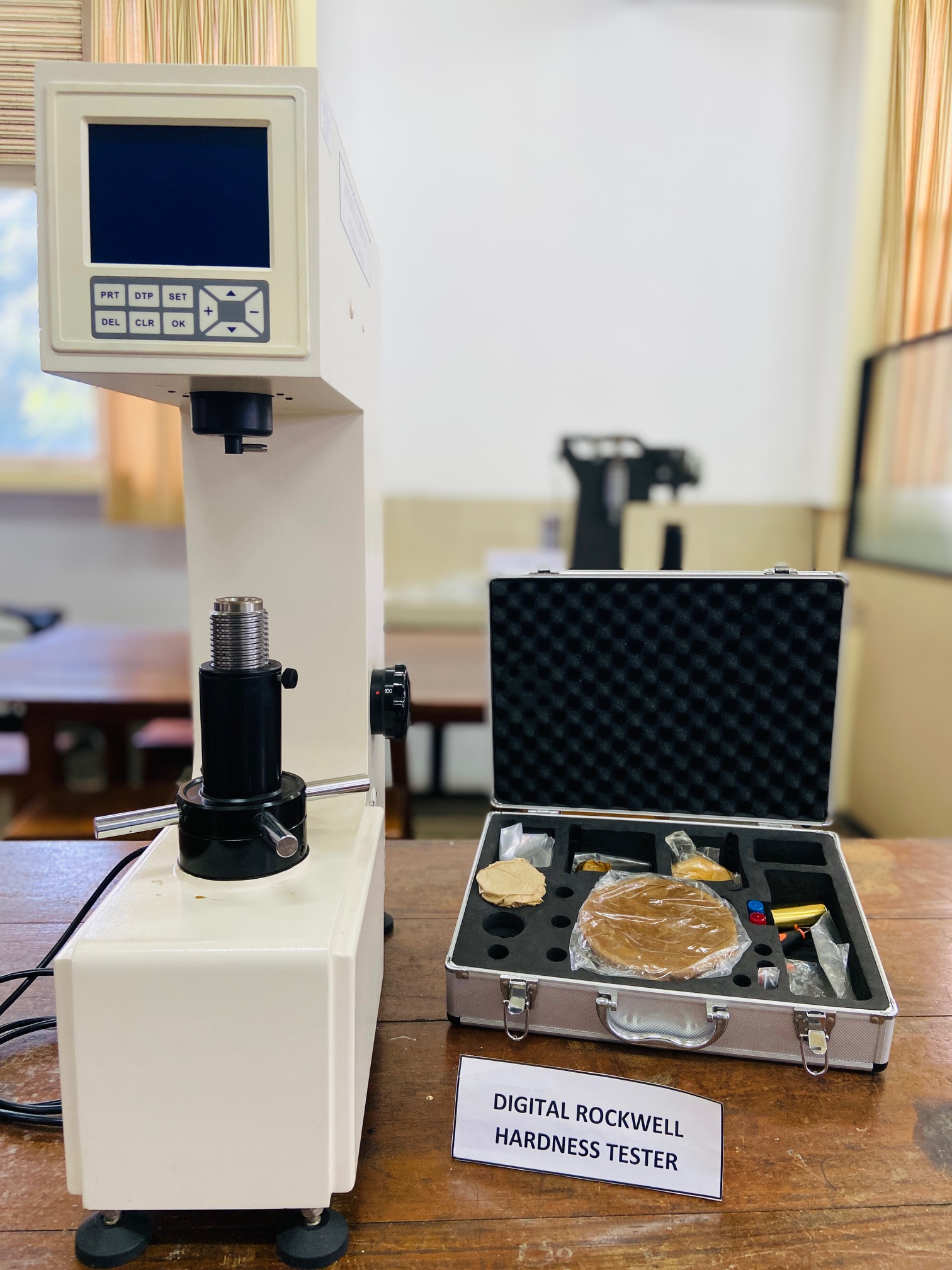

| Conforms to ASTM E-18, ISO 6508 |

| Digital readout |

| Hardness Resolution: |

0.1 of Rockwell unit |

| Display: |

Matrix backlit LCD |

| Languages: |

English, French, German |

| Data Entry: |

Membrane keypad, Menu driven |

| Load Selection: |

Automatic |

| Load duration: |

2 – 50 seconds, can be adjusted |

| Data Output: |

RS232 and USB data output for PC / Printer |

| Power supply: |

110/220V 50/60Hz, 4A |

| Menu Features: |

- Hardness tolerance setting (Upper and Lower limits)- Conversions: Vickers, Brinell, Rockwell, Superficial, UTS - Statistical data: X-bar, s, max, min - Automatic curvature correction for cylindrical and spherical surfaces |

Frame Deformation

(ASTM E18-08 Requires less than +/-1%) |

+/- 0.5% |

Transducer Accuracy

(ASTM E18-08 Requires +/- 1.0μm Regular Rockwell, +/- 0.5μm Superficial Rockwell) |

+/- 0.3μm Regular Rockwell

+/- 0.5μm Superficial Rockwell |

Repeatability

(ASTM E18-08 Requires, 1.0, 1.5 up to 2.0 on the HRC scale) |

0.5 up to 1.0 (HRC Scale) |

Tolerance of applied force

(ASTM E18-08 requires 0.6-0.75%) |

Within 0.5% |

| Dimensions of testing machine: |

Height 28.4” (720mm), Width 8.0” (200mm), Depth 21.7” (550mm) |

| Maximum test height: |

8.0” (200mm) |

| Horizontal Space (from center line): |

6.5” (165 mm) |

| Net weight: |

220 lbs (100 kg) |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

1.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

1.jpg)

1.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

3.jpg)

_FN_500P.jpg)

.jpg)

.jpg)

.jpg)

1.jpg)

.jpg)

.jpg)